KAUST wins highest award in polymer science

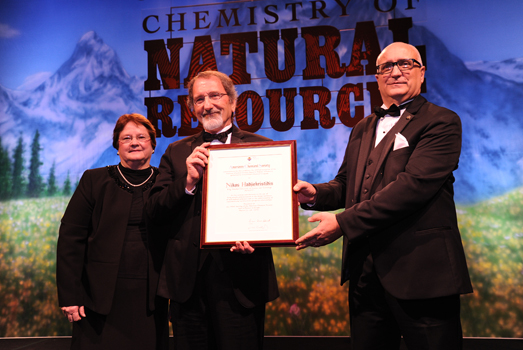

Prof. Nikos Hadjichristidis (center) receiving ACS Award in Polymer Chemistry

KAUST was recently honored at the 249th American Chemical Society (ACS) National Meeting & Exposition, in Denver, Colorado, with the awarding of the prestigious ACS Award in Polymer Chemistry to Prof. Nikos Hadjichristidis. A chemical science professor affiliated with the KAUST Catalysis Center (KCC), Hadjichristidis was presented with the award on March 25, 2015 in front of a packed audience that included senior KAUST leadership, the Director of KCC, all chemical science faculty members, and many of the world's top scientists in polymer science and polymer chemistry – including 2005 Chemistry Nobel Laureate, Robert H. Grubbs. The ACS also organized a two-day symposium in honor of Prof. Hadjichristidis during the national meeting.

The award, sponsored by ExxonMobil Chemical Company, represents the highest honor in the field of polymer science. While much of the polymer science research Hadjichristidis became known for was developed through his illustrious career in his native Greece, he highlighted: "I'm very happy because this is the biggest award I have ever received in my life and it was under the affiliation of KAUST." In addition, the award has given him encouragement to maintain his goal to pursue top research and to educate Saudis. "All my PhD students are Saudi," as he proudly says. He feels very strongly about giving back to the Kingdom.

An important project Hadjichristidis and his group are currently heavily concentrating on is a collaboration with SABIC on polyethylene-based polymeric materials through the exploration of their properties and important potential applications.

A Designer of Molecules

Prof. Hadjichristidis' research focuses on the synthesis of polymeric materials with complex macromolecular architecture (star, comb, cyclic, dendritic). "Much like a designer, I can design molecules with different architecture structures in order to achieve the appropriate properties and applications," as he explains.

His group at KAUST's Polymer Synthesis Laboratory works on various projects including block copolymer membranes for selective water transport, polymeric membranes for fuel cells and batteries, and unusual polymeric materials.

In addition to the collaboration with SABIC, the group's polymeric research is of interest for other industrial applications – including KAUST's strong collaboration with petroleum company ExxonMobil. In fact, petroleum oil provides monomers – which are the precursors for polymers used to manufacture plastics.

One of the most common plastics is polyethylene – which is primarily used in packaging (plastic bags, bottles and films). It's known as a low-density polyethylene. The processability of low-density polyethylene is excellent; and because it's very easy to process, the cost is very low. On the other hand, the mechanical properties of these films are not so good. But there's another polyethylene, called high-density polyethylene, possessing mechanical properties that are excellent. However, the processability of this polymer is unfortunately not good. It's actually quite costly and requires a lot of energy to process.

"Now, the question is what do we have to add to this high-density polyethylene in order to improve the processability," as Prof. Hadjichristidis posits.

The answer lies in the creation of model polymers. This is achieved by studying the processability versus the structure of the model polyethylene. The ultimate result is creating a hybrid structure with excellent mechanical properties.

"By making completely novel polymeric materials, through altering the structure, we can adjust properties, such as elasticity and stress, based on industrial needs," said Hadjichristidis.

Related Links

- by Meres J. Weche, KAUST News