High performance integrated energy storage device reported by KAUST team

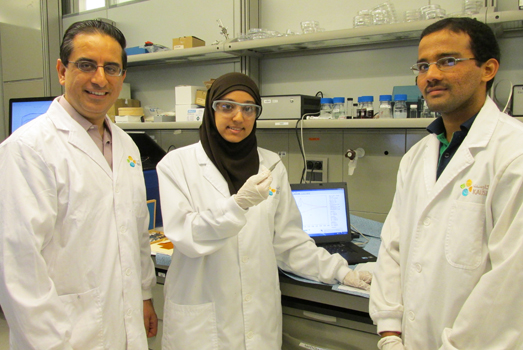

(From L-R): Professor Husam Alshareef, KAUST Ph.D. student Nuha Alhebshi and post-doctoral fellow Dr. Narendra Kurra exhibit their microfabricated supercapacitor in Prof. Alshareef's lab.

A KAUST team led by Dr. Husam Alshareef, Professor of Material Science and Engineering, has developed a microfabricated energy storage device that delivers unprecedented energy and power density higher than current thin film batteries.

"Our microfabricated supercapacitors exhibit superior performance over current state-of-the-art thin film batteries, and can be used to supplement the performance of existing thin film batteries," said Ph.D. student Nuha Alhebshi, a member of Prof. Alshareef's Functional Nanomaterials & Devices research group.

Alhebshi worked with Dr. Narendra Kurra, a post-doctoral fellow in Prof. Alshareef's group, to develop the devices. Their research was recently published in the high-impact journal Advanced Energy Materials (DOI: 10.1002/aenm.201401303).

The devices were fabricated using a combination of top-down and bottom-up fabrication methods, and the researchers used nickel hydroxide (Ni(OH)2) as an active electrode material. The devices exhibited a volumetric capacitance density of 325 F/cm3, resulting in energy density higher than thin film batteries. The microcapacitors also exhibited high scan rate redox activity of up to 500 V/s, a concomitant property of higher power density and capacitance.

The key to the realization of the performance was the control of the nucleation process of the Ni(OH)2 nanostructures deposited by chemical bath deposition. While gold and platinum are typically used as thin film current collectors, the team found that the nucleation and growth of Ni(OH)2 on Ni-based collectors (consisting of a tri-metal stack of nickel/platinum/titanium) resulted in vertically aligned two-dimensional arrays of Ni(OH)2 with remarkable surface area and electrolyte permeability. As a demonstration, the tandem configuration of these microfabricated devices could glow a normalLED. Alhebshi developed the Ni(OH)2 process using chemical bath deposition at room temperature.

"The value of this process is that it is cheap and scalable, and the deposition of active material is done entirely at room temperature," said Alhebshi.

Supercapacitors are energy storage devices that fill the gap between batteries and electrostatic capacitors. The market size for supercapacitors is growing extremely fast, and they are already appearing in many applications, including portable power tools, cranes, intercity trains, and street lamps.

The capacitors fabricated by the KAUST team have a different form factor compared to conventional double-layer or pseudocapacitors. The devices are fabricated on a substrate and can be integrated with other electronic components. For example, the microfabricated supercapacitors can be used to power up microelectronic devices such as microelectromechanical systems (MEMS), microsensors, and nanorobotics.

"The supercapacitors could serve as small scale on-chip energy storage devices to be integrated with microelectronic devices," explained Dr. Kurra.

Prof. Alshareef's group is active in the area of energy storage, focusing on electrode material development for supercapacitors, Li-ion batteries, and more recently Na-ion batteries.

"I believe this research area is a strategic area for KAUST and the Kingdom, and I am happy that we have built a recognized program in this field," stated Prof. Alshareef.

By Caitlin Clark, KAUST News