Developing the Saudi machinists of the future

For Mohammed I. Khalil, Mohammad A. Somer and Bakur A. Fadil, 2020 graduates of the KAUST Core Labs' second Machinist Development Apprenticeship Program (MDAP), exciting opportunities await in the Kingdom's manufacturing field.

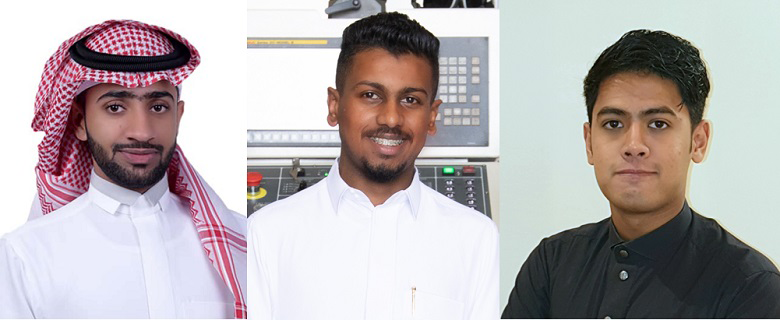

The KAUST Core Labs’ Machinist Development Apprenticeship Program gave its 2020 graduates (from left to right) Mohammad Somer, Bakur Fadil and Mohammed Khalil the skills needed for successful manufacturing careers. File photos.

"MDAP contributes directly to achieving Saudi Arabia's Vision 2030 by training young Saudis on the most advanced technologies and equipping them to work in manufacturing industries in the future," noted Fadil.

"The 18-month-long program aims to develop a world-class machinist workforce through in-depth training opportunities in the Workshops Core Lab, a state-of-the-art work environment," Osman El-Negery, master machinist, supervisor of the Harbor Workshop and MDAP administrator, said. "Our ability to successfully provide a skilled, trained and committed workforce—with team players who are also capable of thinking outside the box—will most certainly be an asset for the Kingdom."

The initial concept for MDAP came into existence in the Core Labs in early 2015 and was spearheaded by Justin Mynar, KAUST associate vice president for research and executive director of the KAUST Core Labs and Research Infrastructure. In creating the program, the University established a collaboration with Yanbu Industrial College, from which all of MDAP's participants were recruited.

MDAP welcomed its first batch of apprentices to campus in the summer of 2017 to begin the program. Apprentices Ali Al-Frshuti, Yaseer Al-Omrany and Muath Alamri completed MDAP in January 2019, taking up positions as technicians and a junior machinist, respectively, in the Workshops Core Lab.

Khalil, Somer and Fadil started MDAP in January 2019 and graduated on August 17 this year. Their graduation was celebrated in an online ceremony on the same day, which was attended by the apprentices, their families, members of KAUST's senior leadership, including Mynar; Samer Samman, chief Human Resources officer; and Professor Donal Bradley, vice president for research; Core Labs directors and staff members; and Dr. Fahd M. Al-Ofie, director of Yanbu Industrial College.

The Core Labs’ second batch of Machinist Development Apprenticeship Program participants celebrated their 2020 graduation in an online ceremony held on August 17. File photo.

Developing outstanding machinists

Before joining MDAP, the current and first batch of apprentices completed their associate's degrees in manufacturing engineering technology at Yanbu Industrial College.

"The success of the previous apprentices encouraged me and my fellow participants to apply for the program," Fadil stated. "After finishing college, I was looking for an apprenticeship program to help me convert my academic knowledge into marketable job skills—so KAUST was the perfect choice for me."

Apprentice Mohammed Khalil is pictured in the Central Workshop, where he prepares a job by reading a drawing to find the best methods and tools to machine a part. File photo.

"I already knew of KAUST as a place that enthusiastically encourages growth through education, training and the use of its vast resources, making me excited to join the program," added Khalil.

"MDAP works on developing machinist general knowledge and skills," El-Negery said. "Therefore, the apprentices are educated on all types of equipment and on the facets of its use. To accomplish this, the program includes classroom instruction and on-the-job training."

"Apprentices are provided with in-depth training that ranges from the designing stages to the manufacturing of parts using state-of-the-art computer-aided design (CAD) and computer-aided manufacturing (CAM) software and manufacturing equipment, such as computer numerical control (CNC) milling, CNC turning, CNC laser cutting and CNC water jet cutting machines," he continued. "They work in the Workshops Core Lab's Machining section, which includes the Harbor and Central Workshops."

Based on the daily job requests received in the Workshops Core Lab, the apprentices were assigned with jobs to complete. To enhance their training tasks, they were also given different weekly mentors by El-Negery, and they shadowed each mentor.