Giving old technology a modern update

KAUST Associate Professor Peng Wang is developing new solar desalination methods to increase efficiency and minimize heat losses. File photo.

-By Sonia Turosienski, KAUST News

The water in the world's oceans has long captivated engineers, philosophers, sailors and scientists. As early as Aristotle, people have speculated about the difference between salty water and what was then called "sweet" water. One reason for this interest was the possibility of using saltwater as a source of fresh water.

Greek sailors discovered that condensed vapor from boiled sea water could be collected on sponges to produce fresh water. Early European texts from the Middle Ages describe how seafarers experimented by filtering water through sand, distilling water through the use alchemic stills and even attaching fleeces to the sides of ships at night to collect water condensation. Another method was filtration through wax vessels or the walls of an earthenware vessel. These techniques had mixed success, so the motivation to produce fresh water at scale remained.

Turning up the heat

It was not until 1551 that the issue of water desalination was paired with solar energy. Arab alchemists were the first to desalinate seawater by heating vessels though concentrated solar radiation produced by concave mirrors—the first known use of a solar still. Since then, solar stills have been in use on a commercial and industrial scale in many parts of the world.

Solar distillation is based on the natural process of water filtration. A solar still usually consists of a closed basin of salty water. The basin is housed by a transparent cover commonly made of plastic or glass to allow solar radiation to make its way through. The water in the basin is heated and the vapor condenses as it makes contact with the basin cover, which is at a lower temperature because of its contact with the outside air.

While the system is simple in its fundamental process, the main challenge is to maximize efficiency and minimize energy losses. Currently, solar stills can reach efficiencies from 30 percent to 50 percent.

KAUST Associate Professor Peng Wang and colleagues from the University’s Water Desalination and Reuse Center are developing new and innovative systems for solar water desalination. File photo.

A 21st century update

Peng Wang, KAUST associate professor of environmental science and engineering, and colleagues at the University's Water Desalination and Reuse Center (WDRC) are giving solar water desalination a 21st century update. Wang and his team have developed an innovative system that more efficiently vaporizes water through heat generated by solar energy through the use of interfacial heating. Two unique features of Wang's system work together to make the water vaporization process work at near perfect efficiency.

The design uses a photothermal material that can capture the entire spectrum of sunlight and convert this energy into heat, nearing 100 percent efficiency. The photothermal material lines the bottom and sides of the system's cylinder walls. Secondly, the design uses interfacial heating through 3-D cylinders that "cup" the energy that is otherwise lost as a result of sunlight reflection and thermal radiation heat loss. These two aspects of the design contribute to the highly efficient production of the resulting solar-generated water vapor.

The photothermal material created for the solar distillation system in Wang's group has other applications besides its perfect solar-to-heat conversion efficiency.

"Our photothermal materials offer high mechanical and thermal stability, meaning they can be regenerated physically and thermally once fouled during practical applications," explained Wang.

On a system level, the same design "works with many different water sources—saltwater, wastewater, groundwater," said Wang. "The next step is to convert the water vapor into liquid water through condensation. This is a complicated part of the process and deserves our research attention next."

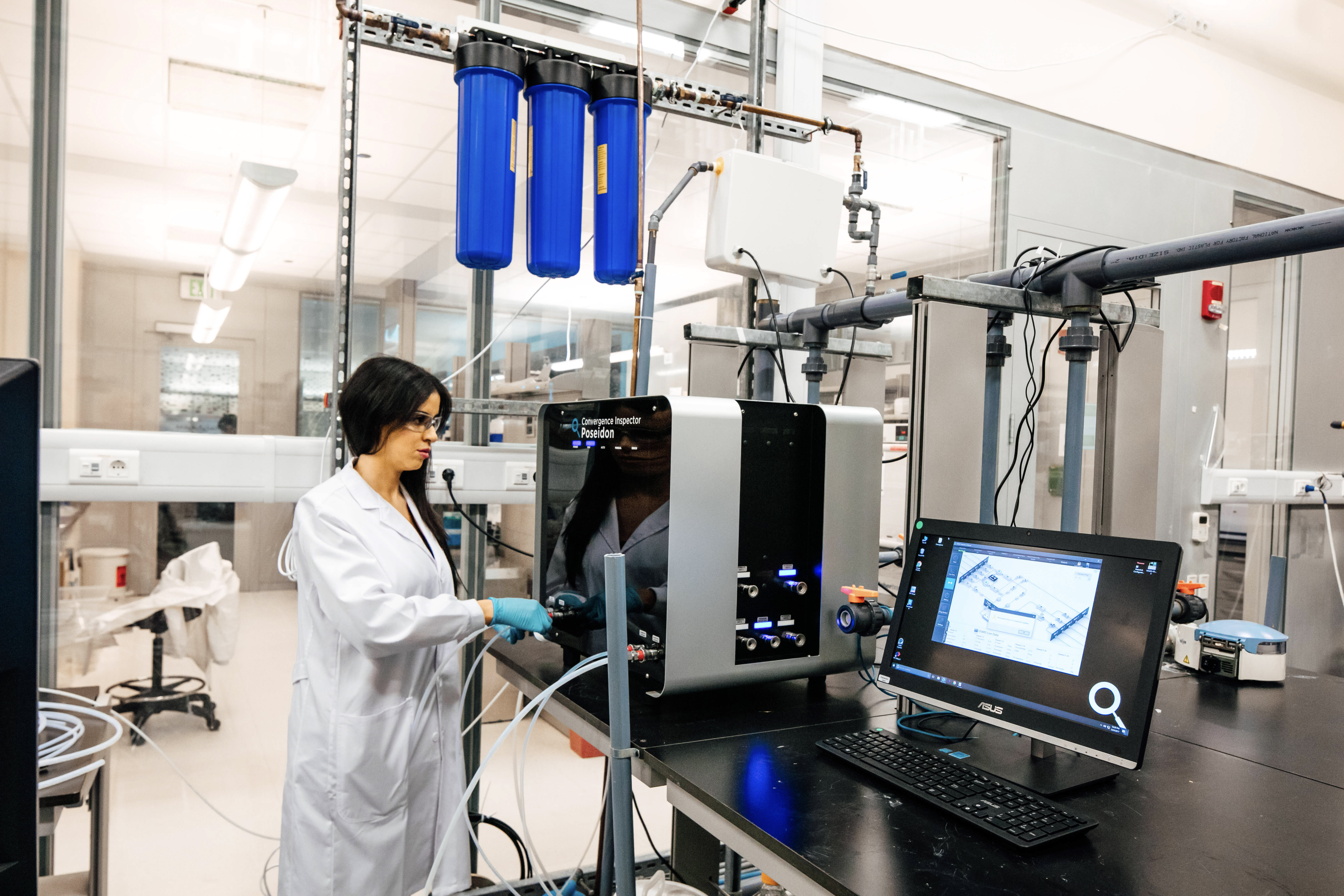

Solar desalination has been a focus for the the University’s Water Desalination and Reuse Center. File photo.

Desalinating the future of the Kingdom

Saudi Arabia is no stranger to large-scale water desalination, ranking as one of the world's largest water desalinators. Currently, half of the Kingdom's domestic water production is produced by desalination plants. In the early 1900s, one of the first water distillation units was opened in Jeddah and was powered by coal. Later, in 1926, the government ordered two distillation condensers to bridge the water shortage during the Hajj season, and the success of these plants led to the further installations around the Kingdom.

Water scarcity still remains a top priority, and any improvement to make the process more efficient and sustainable will make a big impact. In 2017, Revolve Water reported that domestic water consumption in Saudi Arabia was nearly 1.5 times the OECD average. A 2010 research paper forecasts domestic water demand to increase three-fold by 2040 in the moderate scenario and four-fold in the pessimistic scenario compared to 2010.

Wang and his team are proposing a fundamentally different way to couple solar energy and desalination.

"Traditional solar desalination uses concentrated solar energy to heat water. The overall efficiency of a system is typically not satisfactory. That's why we have gone into this area—we believe the combination of photothermal material and interfacial water heating can improve on what exists," Wang explained.

Earlier this year, it was announced by the Ministry of the Environment, Water and Agriculture that nine new desalination plants will be built along the Red Sea in the next 18 months. The Kingdom is well-poised to capitalize on solar-powered water desalination, as it receives some of the highest levels of solar irradiation in the world and has a long coastline. Wang's 3-D solar steam generation system design is an innovative and promising development in water desalination and reuse.

Related stories:

-

KAUST takes semi-saline irrigation to a new level

-

Harnessing the global potential of wastewater

-

The internet of sea things

-

Igniting biotech at KAUST