Plasma-enhanced chemical vapor deposition reactor will expand University's research capabilities

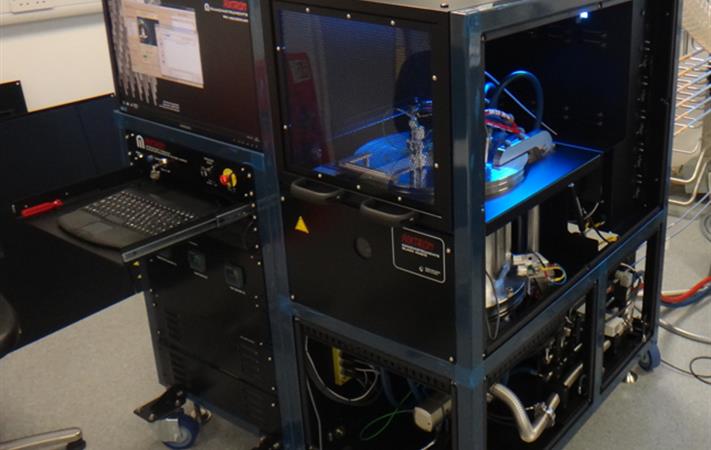

KAUST's BM Pro plasma-enhanced chemical vapor deposition (PE-CVD) reactor. Photo courtesy of AIXTRON Ltd.

Pedro Da Costa, KAUST Assistant Professor of Material Science & Engineering, is excited about the University's recent acquisition of what he calls "a unique piece of kit" – KAUST's BM Pro plasma-enhanced chemical vapor deposition (PE-CVD) reactor, a dedicated system for wafer-scale deposition of graphene and carbon nanotubes.

The reactor, which is capable of handling up to 4-inch substrates, "is basically a standard in the best groups in the world that are dedicated to this kind of research," explains Prof. Da Costa. It will initially be used by his KAUST research team.

AIXTRON SE, the German company that built the reactor, is one of the key providers of growth equipment for the semiconductor industry worldwide. Dr. Frank Schulte, AIXTRON's Vice President, stated the company was "delighted about the first order from KAUST. Our BM Pro system is based upon…[a] concept which delivers both uniformity and scalability, rapid heating and plasma-based processing to successfully grow mono and multi-layer graphene and various nanotubes, and [has] low cost of ownership and maintenance."

The PE-CVD reactor is "the Rolls-Royce of R&D reactors for carbon nanostructures," says Prof. Da Costa. "Unlike normally designed reactors, here gas is dispensed from the top of the reactor like water coming from a bathroom shower," he explains. This means there is a more uniform distribution of reactants onto the substrate.

"This type of reactor is designed from the ground up to do carbon growth, and will be dedicated just to this task. Because of this, we will minimize the risk of problems from contamination," Prof. Da Costa says. "Based upon my previous stay researching at Cambridge University in the U.K., I was aware this was really the best machine for this kind of work. To me, it was a no-brainer – if I could get hold of one of these systems, that was what I wanted to go for."

Prof. Da Costa is eager to begin using the reactor, which is due to arrive at KAUST in October. It will be placed in a purpose-built lab in KAUST's Ibn Sina building. The lab is currently under construction. But Prof. Da Costa notes that the reactor "is not a plug-and-play kind of machine… It takes about two weeks to install it and train the operators, so it needs dedicated people to work with it and to optimize the growth protocols for each individual type of structure." For this reason, it will first be used by his research group, and later in collaboration with other researchers at KAUST.

Prof. Da Costa plans to have two main growth reactors for his group: AIXTRON's BM Pro, entirely dedicated to pure carbon nanostructures deposition; and a machine for heterogeneous carbon-based materials. "These reactors will be the two main workhorses for my group's research," he explains.

Armed with these deposition tools, Prof. Da Costa believes his group will be able to "expand our research in this rapidly growing field with the aim of finding a wide range of new applications. AIXTRON's world-leading reactor will certainly support us in our work."

- by Caitlin Clark, KAUST News