Sensing the future

The advent of 2D materials, such as MXenes, opens up exciting new avenues for sensing devices used in physiological and biochemical signaling.

What if science could find a way to replicate or mimic human skin effectively? Such an engineering feat would require taking into account certain vital functions such as sensing, evaluating, discriminating, and adapting to multiple external stimuli. Electronic skin, or e-skin, represents one of the next frontiers in materials science.

Yichen Cai, a postdoc in Professor Vincent Tung's 2D Materials Lab, from the KAUST Catalysis Center (KCC) and fellow postdoc Jie Shen, from Professor Yu Han's Nanostructured Functional Materials group, in the KAUST Advanced Membranes & Porous Materials Center, joined forces to tackle some of these challenges facing the potential wider adoption of e-skins.

Their efforts are being led by Dr. Vincent Tung, associate professor of materials science. Two years ago, Tung took over the 2D Materials Lab – which had previously been helmed by Professor Lance Li, one of the most prominent researchers in the 2D materials field.

Tung immediately sought innovative ways for the group to continue standing out in a crowded field. The wafer-scale synthesis of next-generation non-silicon electronics is one of the different directions the current group members are focused on.

Associate Professor of materials science Dr. Vincent Tung.

"Yichen and Jie brought the research to the 2D materials group. This is completely their idea, and I am forever grateful for their contribution," said Tung. "We were able to build a very strong and also a very innovative team."

The group's research on electronic skin sensors was recently published in Science Advances.

Expanding the possibilities of the electronics industry with 2D materials

Silicon-based devices have primarily dominated the electronics industry due to the low materials cost. But the demands of new generation electronics call for novel functionalities enabling a more compact, sustainable, flexible and efficiently powered electronic system.

"Actually, you can see 2D materials as a very visible nexus to connect, or to bridge, the gaps between many fields, especially toward next-generation electronics, optoelectronics, sensors or even composites," said Tung. "There are many intriguing properties of 2D materials."

The properties of 2D materials allow them to be conveniently manipulated through composition, structure and dimensionalities. This means there's an added freedom to slash the active components down to mere atoms in thickness—an ideal recipe for realizing the ultimate flexible electronics.

"We usually deal with these hundreds of micrometers of flakes for real-world applications such as e-skins, semiconductor electronics, sensors or even catalysis," as Tung outlined.

"The key point is 2D materials such as graphene, graphene oxide and MXene can be dispersed in solvents, which means it's very easy to large-scale produce these kinds of materials." Shen further elaborated.

As part of the work they have published, the team has dispersed these materials, which show excellent electronic properties, into water to make a large area of thin films on the hydrogel materials.

Replicating the properties of human skin

One of the industries where these new material structures are particularly needed and have the most potential for impact is healthcare. The advent of 2D materials, such as MXenes, opens up exciting new avenues for sensing devices used in physiological and biochemical signaling.

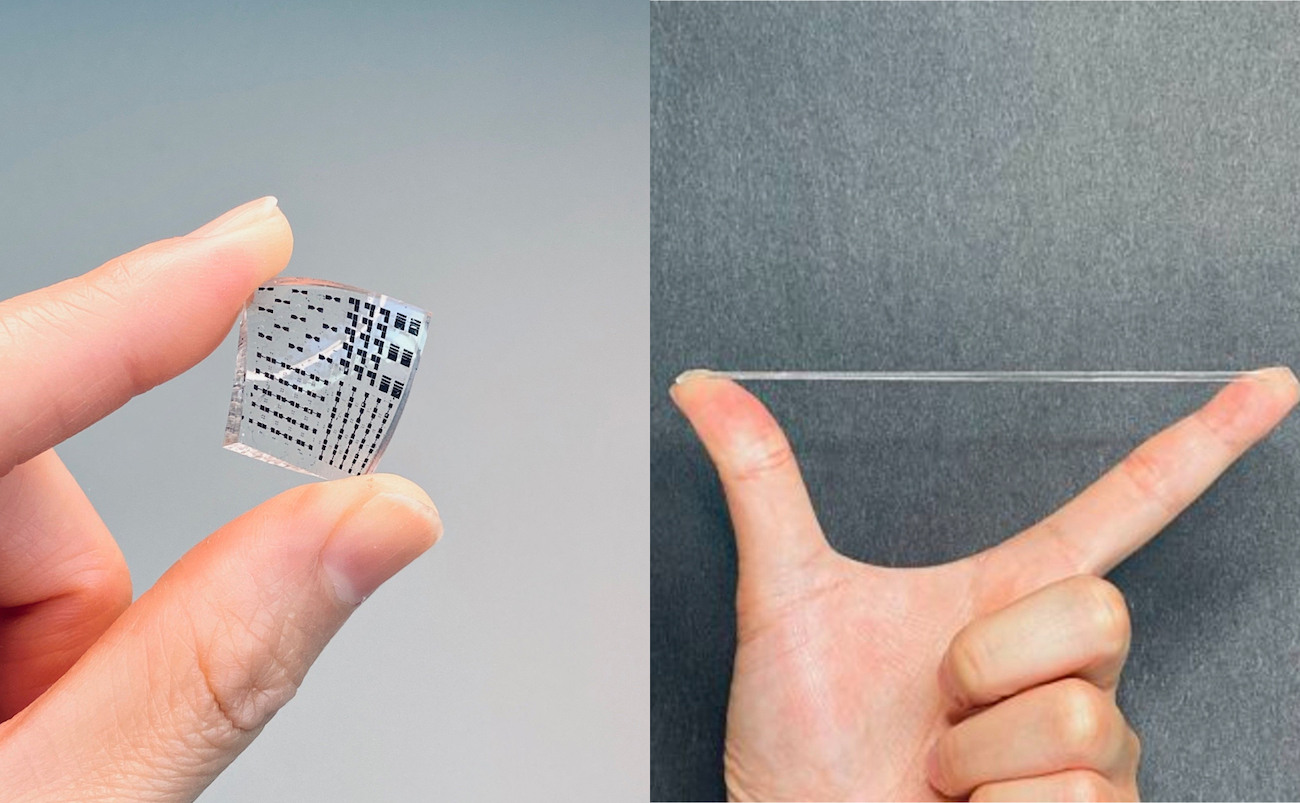

E-skins represent an ideally-suited application. In addition to being ultra-thin, 2D materials are highly transparent. "For flexible electronics applications, we can make transparent e-skin," said Cai. "So it's easy to attach to the body and to improve the aesthetics and lifetime of devices."

KAUST Postdoctoral Fellow Yichen Cai from Professor Vincent Tung's 2D Materials Lab, from the KAUST Catalysis Center (KCC)

The KAUST team uses a hydrogel to emulate the properties of human skin. "The hydrogel is a polymer made up of 90 percent water, and it's very flexible. We can stretch it to 28 times and can recover very quickly. It is similar to our real skin. It can also be easily attached to our body," Cai explained.

They achieve the unique hydrogel-based structure design by incorporating 1D polypyrrole nanowires at the interface layer and use the 2D MXene as a sensing layer.

The resulting e-skin exhibits multi-sense and multi-mode capabilities and functions – which means the e-skin can detect signals or stimuli from different directions. For instance, the two-way sensing properties of their prototype e-skin mean it can detect signs of change in blood pressure and sense objects or external stimuli at a close distance.

In the future, Cai hopes the hydrogel can be used for drug delivery and other functions.

Chemical sensing: Looking further into industrial applications

Some of the other applications include chemically functionalized MXene that could have sensing capabilities for chemicals like toxic liquids or gases. "It's entirely possible," Shen said.

KAUST Postdoctoral Fellow Jie Shen from Professor Yu Han's Nanostructured Functional Materials group, in the KAUST Advanced Membranes & Porous Materials Center.

"Once we integrate these kinds of functions into the sensing layer, that means we can have sensing capabilities of this kind of chemical function."

For example, e-skin could be used as e-tape around industrial pipes to detect cracks on the pipes wirelessly. Companies like Saudi Aramco can use AI-enabled networks to obtain signals of such anomalies.

"This is one of the applications that you can imagine or envision in the future," said Tung. We can also imagine the ability to detect harmful chemical combinations and helping robots detect explosives at airports."

"Real-world applications are infinite, and we are just on the tip of the iceberg. Electronic skin is basically the first step. We have more interesting work to do and publish soon. 2021 is going to be a very exciting year for the 2D Materials Lab," Tung said.

Related stories

- Smart skin for flexible monitoring

-

A healthy boost to precision medicine in KSA

-

KAUST developed fish wearable technology wins CES Innovation Award