Laser focus on air pollution

A laser-based sensor that can detect the first traces of escaping gas could enable petrochemical plant operators to catch and fix leaks before they become threats. The sensor system developed in collaboration between KAUST and Saudi Aramco aims to safeguard workers, help protect the environment and increase plant efficiency.

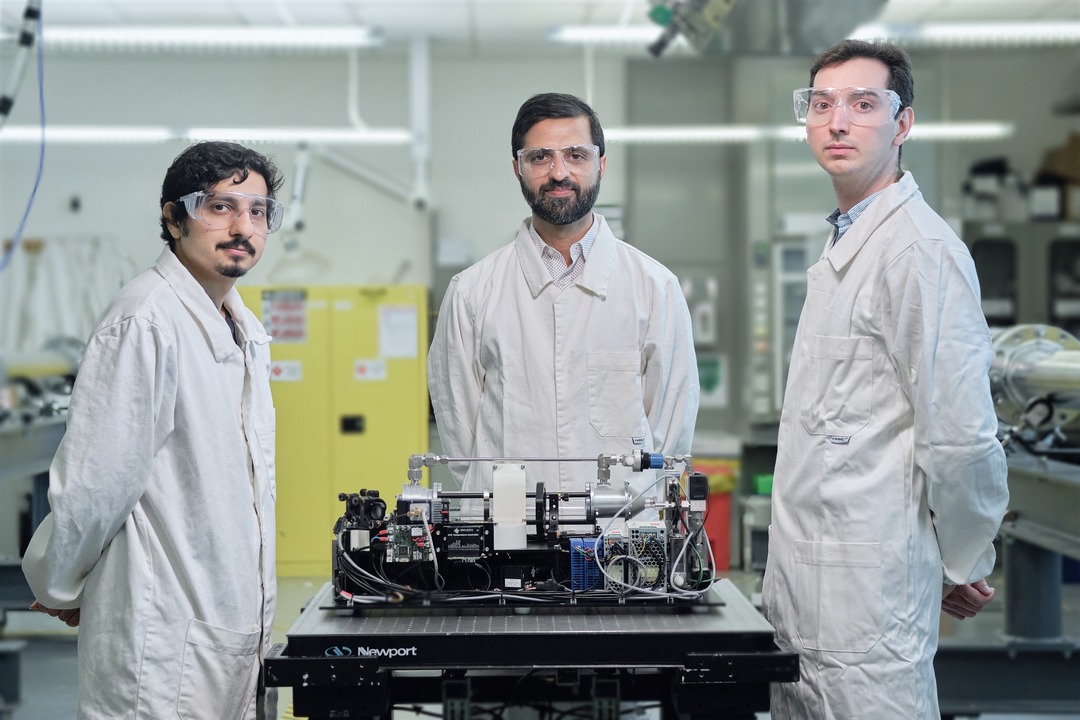

“The sensors we are developing are portable, highly sensitive, selective and respond quickly,” explains KAUST mechanical engineer Aamir Farooq, who co-led the project. The team’s machine-learning-powered laser sensor technology can not only detect the first traces of a leak, but positively identify the specific gas that is escaping, allowing repair crews to rapidly pinpoint the source of the leak.

Previous versions of sensors are only able to detect large gas leaks. “We want to be proactive by looking for a localized type of solution,” says Hydrogen Economy Lead for Aramco Adrian Cavazos Sepelveda.

Conventional semiconductors tend to be based on semiconductors and electrochemicals. However, we are developing laser-based systems,” explains Farooq. This new type of sensor system combines innovations in optical technology with the latest machine learning methods expected to improve sensor performance.

“The sensor takes advantage of modern machine learning algorithms, such as autoencoders and augmentations, where we train our sensor on a large set of data to separate the signatures of different gases,” he says. “As a result, they are highly selective and are able to detect tiny amounts of specific gases.”

To demonstrate the system’s capability, the team showed it can differentiate four closely related industrial gases - benzene, toluene, ethyl benzene and xylenes – known collectively as BTEX. “They all have very similar chemical structures, which makes their differentiation highly challenging,” Farooq says. “The current sensors are not able to do it.” The new sensor could detect and differentiate each member of the BTEX family in trace quantities. The next step is to manufacture a prototype sensor for field testing.

“Because these sensors are small and portable, we could deploy them in very large numbers to ensure the safe and optimal operation of petrochemical facilities,” Farooq says. “The technology is unaffected by Saudi Arabia’s high temperatures and humidity”.

"Through our partnership with KAUST, we envision a collaborative journey centred on sustainable innovation. By merging academic expertise with industry insights, we aim not only to deploy transformative technology, but also to incubate a culture of continuous innovation,” Says AbdulWahab Alghamdi, Head of KAUST Aramco Upstream Research Center. “Our joint efforts aim to drive the creation of environmentally conscious solutions."

“Our aspiration extends beyond borders. Leveraging KAUST's pioneering research and our industry experience, we are poised to introduce technology that transcends geographical boundaries. Our ambition is to not only revolutionize our operations within the Kingdom but also to share these advancements worldwide. This technology stands as a testament to our dedication to global operational excellence."