Core Labs Launch Saudi Scientific Glassblowing

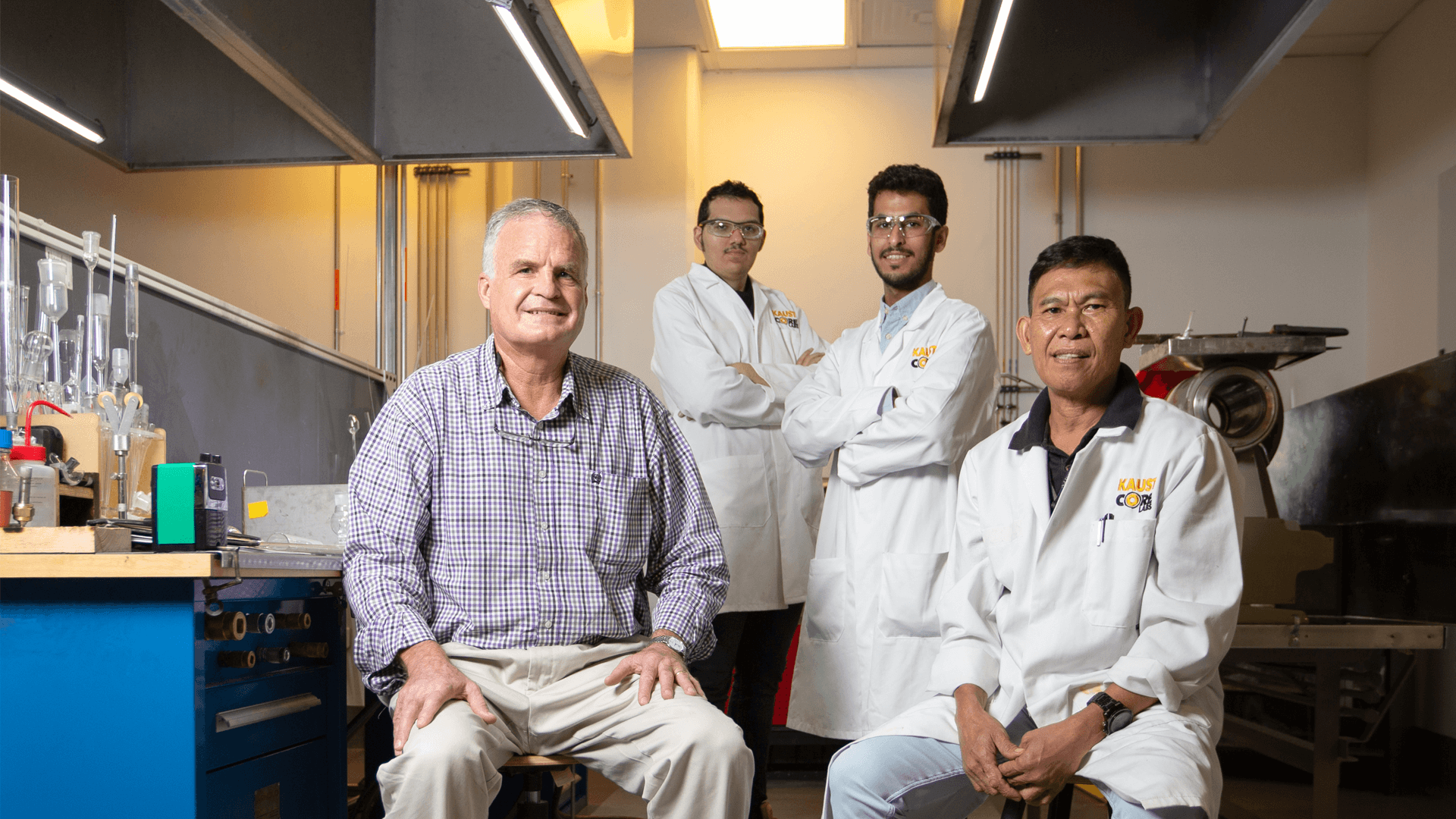

LaVon Bennett, former KAUST Workshops Core Lab manager; scientific glassblowing apprentices Faisal Nour and Mohammed Al-Amri; and Emilio Harina, master glassblower, are pictured in the University’s Glass Shop. Photo by Khulud Muath.

Picture the inside of a laboratory, such as the top-notch research labs at KAUST, and one of the first images that comes to mind might be rows of sparkling scientific glassware, like test tubes, beakers, cylinders and flasks, awaiting use.

Scientific glassware and the art of scientific glassblowing are crucial for modern-day research across the biological, chemical, engineering, medical and pharmaceutical fields, with almost all scientific researchers utilizing glassware at some point in their work. Without the skills of glassblowers—artisans who bring their high-level training into the research field—it is difficult to imagine the advances that have been made in science and research.

At KAUST, scientific glassblowing is carried out in the Workshops Core Lab, which houses the University's Glass Shop. There, master glassblowers Ernest Neil Davison and Emilio Harina work primarily with borosilicate and quartz glass, designing, fabricating and repairing glassware used in research across KAUST's three divisions and with the University's industry partners. The on-campus Glass Shop is the only facility in the region leveraging such unique infrastructure and expertise to offer highly specialized services.

To pass on highly specialized scientific glassblowing skills to a new generation of Saudi glassblowers, Davison and LaVon Bennett, former Workshops Core Lab manager, developed the KAUST Scientific Glassblowing Apprenticeship Program, the first glassblowing program in the Kingdom. The program's first two apprentices, Faisal Nour and Mohammed Al-Amri, began training virtually with the Workshops Core Lab team in June 2020, and on-campus training began in October 2020.

Expanding a unique trade

"The Workshops Core Lab developed the apprenticeship program to bring the trade of scientific glassblowing to the Kingdom in a manner that makes it sustainable for the future," Davison said. "Scientific glassblowing is a small but growing field around the world, but in Saudi Arabia, it is almost nonexistent. We envision our program becoming internationally recognized and that graduates world-renowned professionals and makes KAUST into a center for expert glassblowing consultation."

It is expected that Nour and Al-Amri will train with Davison and Harina at KAUST for five years, at which point—after a total of 7,000 hours of mentorship and training—they will become journeymen glassblowers. After 10 years of working and refining their skills, they become master glassblowers.

"We anticipate our first two apprentices as being the first batch of many to graduate as journeymen," noted Jason Serin, Workshops Core Lab manager. "Then, we expect they will make a significant impact in the nation and around the world by establishing glassblowing departments that produce both routine and bespoke items highly sought after by research and development organizations."

Faisal Nour (left) and Mohammed Al-Amri (right) are the first two Saudis to take part in the University’s Scientific Glassblowing Apprenticeship Program. File photos.

Learning specialized skills

The program focuses on engaging the apprentices in daily instruction and one-on-one training; Glass Shop floor manufacturing experience; and the fabrication and repair of customized experimental scientific apparatuses for KAUST users and industrial partners. A detailed program instruction book prepared by Davison is followed by the apprentices, which lays out their training in stages over the five-year period. Apprentices also learn about all aspects of Glass Shop safety and storage procedures; blueprint reading; the preparation and nature of glass; hands-on bench glassblowing; lathe training; polariscope use for glass internal stress detection; and the annealing of glass.

"The program is long, and learning the trade can be frustrating, as glassblowing is challenging and requires natural tenacity and skill," Serin said. "Our apprentices will be tested on their abilities to endure difficult learning experiences and succeed."

Nour and Al-Amri, however, are dedicated to their choice of program. Nour joined KAUST after receiving his bachelor's degree in finance from the University of Business and Technology in Jeddah, and Al-Amri joined after completing his associate's degree in mechanical maintenance engineering from Yanbu Industrial College. Despite their different educational backgrounds, both are passionate about handicrafts, art, designing and drawing, and the program fit their hobbies and interests well.

"Scientific glassblowing is a trade that is now experiencing a resurgence, and the KAUST apprenticeship program is an amazing opportunity to ride the wave at the right time in a field that's very interesting to me," Nour said. "So far in the program, we've learned about many types of glass and their usage, as well as techniques to manipulate and handle the glass and the use of graphite tools to reshape it. We have also begun drawing and designing pieces of glassware requested by customers."

"Every day in the program, we face unique challenges with different glass types, shapes and designs," noted Al-Amri. "Mr. Davison has helped us understand and learn glassblowing techniques through research topics over the last seven months, and we've shadowed Mr. Harina to learn about his creative techniques to melt multiple glass types together."

"We are looking forward to begin melting glass," Nour said. "It's challenging to work with fire and sharp tools, yet it's also exciting—the more challenging a task is, the more eager I am to work on it until I master it. Through new knowledge, I then become motivated to come up with innovative ideas and invest in myself to become a master of the glassblowing trade. We apprentices want to inspire others to join in the program and the field."

Neil Davison, a master glassblower from the KAUST Workshops Core Lab, produces complex scientific glassware for the University’s researchers in the on-campus Glass Shop. Photo by Khulud Muath.

Glassblowing for a new generation

Serin and the Workshops Core Lab team plan to bring a new cohort of apprentices into the program every two years.

"Upon completion of the program, we expect the apprentices will have exciting job opportunities for life," Serin said. "Graduates might find themselves developing and expanding glassblowing shops in other universities or in industry, such as in oil and gas companies."

"We apprentices are the program's pioneers, and we hope to achieve outstanding results that will benefit the Kingdom and its Vision 2030," noted Nour. "I aspire to become an expert in the field and then teach others about and mentor them in my amazing trade. One day, I would even like to begin my own glassblowing program that inspires others to draw, design and craft glass."

"Through completing the program, we also hope to create new job opportunities in Saudi Arabia," he continued. "Providing specialized scientific glassware to the Kingdom from within the Kingdom will be a great opportunity to increase jobs for Saudis."

"I believe my future skills as one of the country's first scientific glassblowers will be very helpful for Saudi universities and different companies to achieve their research goals," Al-Amri said.

"Teaching and passing on glassblowing skills in the Kingdom and wider region is one of the most valuable gifts that can be given," stated Martin Glasspool, Workshops Core Lab lead production engineer. "Saudi Arabia will be supported hugely by our exciting and ambitious program."

"I'm delighted to have been part of the apprenticeship program from the start," Bennett said. "Through the support of KAUST, we are putting Saudi Arabia on the world stage for the training and teaching of the old art of scientific glassblowing."

Related stories:

- A milestone in Saudi scientific diving

- KAUST Core Labs launches Machinist Apprenticeship Development Program

- Shaheen sets subsurface mapping world record

-

The Prototyping Core Lab: Supporting innovation and creativity in KAUST and the Kingdom