KAUST and the global air conditioning revolution

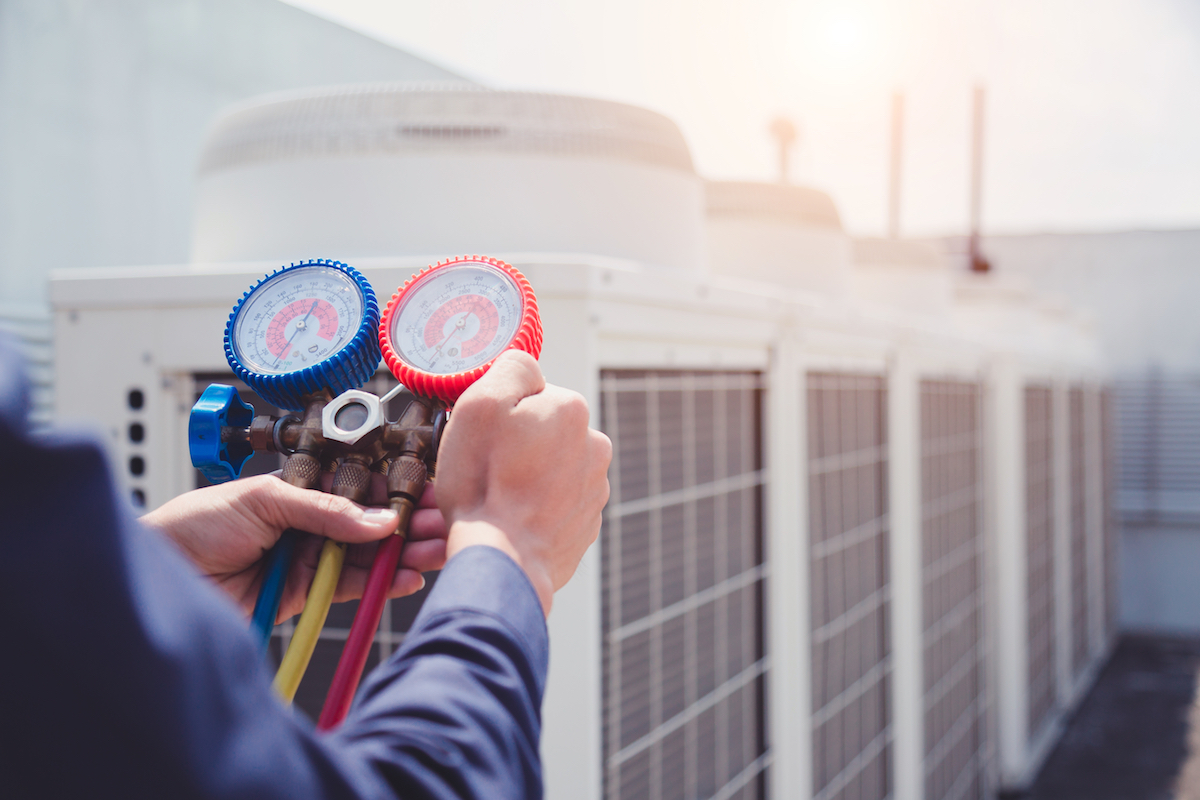

KAUST researchers—including Professor Kim Choon Ng—focus on addressing the pressing challenge of growing electrical consumption in cooling technologies. Image courtesy of Shutterstock.

-By Tanya Petersen, KAUST News

No one likes suffering in discomfort from a hot day at work or home. These days, air conditioning offers a productivity improvement that has permeated our daily lives. Indeed, over the past two decades, the global demand for air conditioning has increased at around 3 to 4 percent annually, and the world market value of cooling and refrigeration exceeds $110 billion annually.

Air conditioners now use 9 percent of the world's total annual electricity production. It is predicted that by 2050, the rate of energy consumption will double, rising to around 20 percent of total global electricity production. In Saudi Arabia, up to 70 percent of the electricity used in the summer months is for cooling systems.

Much of this increase can be attributed to the roll out of new air conditioning units due to rapid population growth and higher global disposable income.

The United States, with a population of around 325 million people, consumes more energy for air conditioning than the entire rest of the world. According to the U.S. Department of Energy, each home with an air conditioner emits about 2 tons of carbon dioxide into the air each year. Given that most electricity worldwide continues to be generated using fossil fuels, it's not hard to do the math for emissions.

Air conditioning in most homes emits around 2 tons of carbon dioxide into the air each year. Image courtesy of Shutterstock.

A growing use of water to cool

Air conditioners in commercial and industrial buildings also need water for the rejection of heat emanating from the refrigeration cycle via the cooling towers. In Silicon Valley alone, the water used to cool California's estimated 800 data centers each year could fill approximately 158,000 Olympic-sized swimming pools.

China and India are catching up fast. The proportion of homes in China with air conditioning spiraled from 8 percent to 70 percent between 1995 and 2004. More than 60 million cooling systems are sold there every year—more than eight times the number sold in the U.S. per year. Ironically, air conditioning contributes to climate change through increased carbon emissions—but its increased use alleviates people from the consequences of a warming planet.

Innovators have promised more efficient devices over the past decade. Researchers from the University's Water Desalination and Reuse Center are now at the forefront of attempts to address the challenges of growing electrical consumption in cooling. KAUST Professor Kim Choon Ng; KAUST research scientists Dr. Muhammad Wakil Shahzad and Dr. Muhammad Burhan; and KAUST postdoctoral fellows Faheem Akhtar and Chen Qian explore ways of improving the energy efficiency of chillers in the cooling industry, reducing costs and helping to cut CO2 emissions from the cooling sector.

KAUST Professor Kim Choon Ng (pictured) and a team of researchers from the University's Water Desalination and Reuse Center investigate methods of improving the energy efficiency of chillers in the cooling industry. Photo by Khulud Muath.

Innovation urgently needed

"The major problem plaguing the cooling industry is the stagnant energy efficiency of conventional refrigerant-based chillers," stated Ng. "Since the 1960s, we have seen improvements in the efficiency of roto-dynamic compressors thanks to advances in the aviation industry. Other improvements in heat exchanger efficiency and improvements in refrigerant properties have seen improvements since the 1990s, but these have been more gradual. Today, we see an urgent need to develop innovative cooling processes to further improve efficiencies—otherwise we will further exacerbate global warming."

The team investigated a novel approach that dehumidifies outdoor air before it enters a cooling system, allowing more efficient cooling without chemical-based refrigerants but using techniques such as water evaporation.

"These are game-changing processes," noted Shahzad, who also specializes in energy recovery from desalination plants. "When implemented in buildings, we should see a quantum drop in the specific electricity consumption from 0.85 kilowatt per refrigeration ton (kW/Rton) to as low as 0.5±0.05 kW/Rton, leading to significant savings of energy and water—that is enormous."

Shown here is an in-house indirect evaporative cooler, or IEC, of nominal 1 Rton cooling capacity undergoing testing at KAUST. Image courtesy of Kim Choon Ng.

Energy-efficient chillers

Shahzad explained that the new approach to the cooling systems' design should make redundant much of the heavy equipment found in conventional chillers. For example, this includes refrigerant-based compressors, chemical refrigerants, chilled and cooling water pumping circuits with large pipes and the massive water-cooled cooling systems. Replacing this equipment with a much more efficient system would free up valuable commercial space in larger buildings.

While still in its formative stages, many research centers, universities and manufacturers are working hard in similar areas to improve the energy efficiency of air conditioning in buildings. The potential of this new approach to air conditioning systems is tremendous, with the prospect of seriously addressing energy consumption challenges in the global cooling sector.

"We see many opportunities to improve efficiencies across large sectors of the economy," Shahzad added. "[With] KAUST's [research] support, we are embarking [on] the translation challenges from laboratory to pilot prototypes to realize the energy-efficient chillers for all building and residential homes, ensuring a sustainable cooling future for us all."