Sustainable membranes for future energy

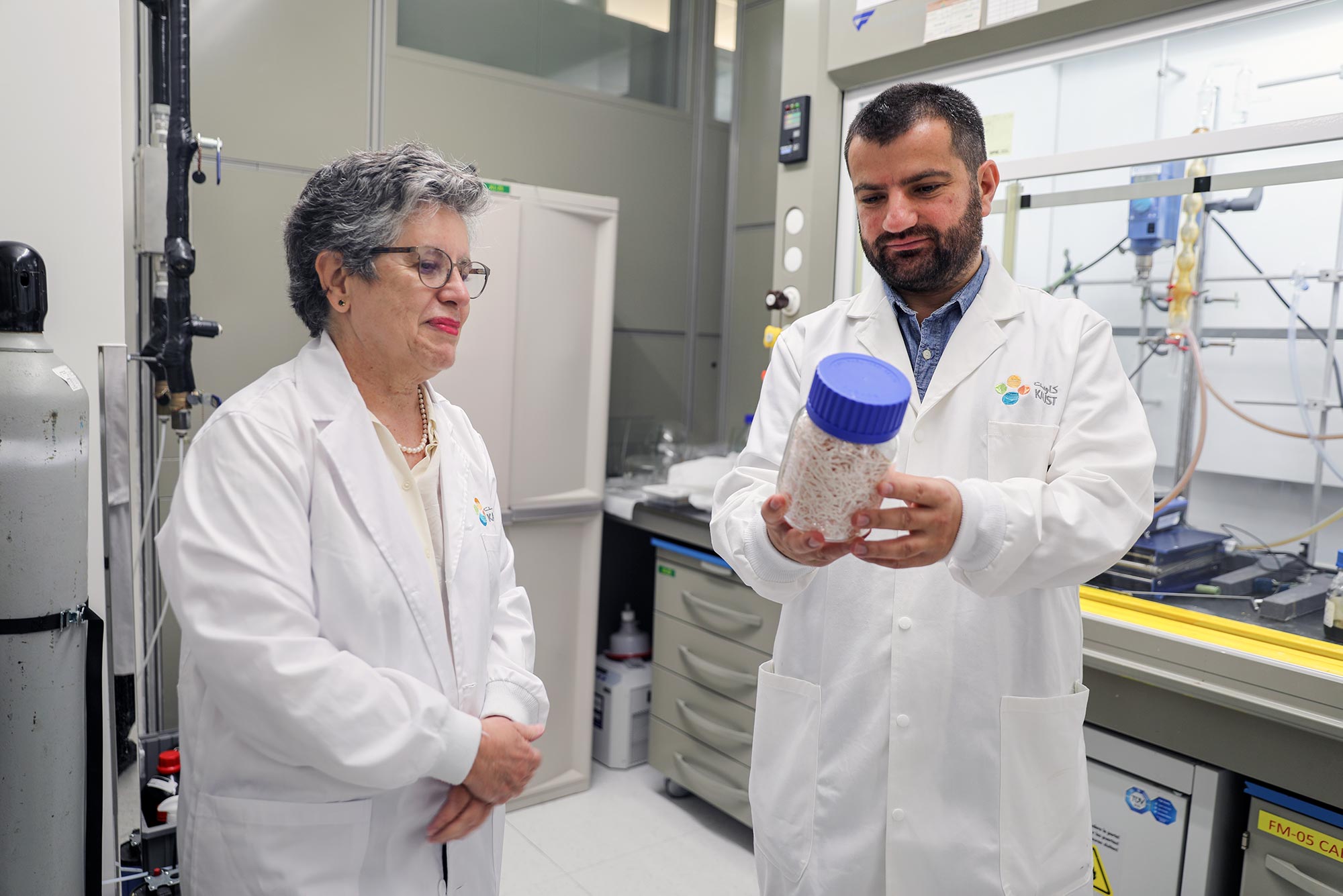

Portrait of Dr. Stefan Chisca (left), KAUST research scientist, and Dr. Suzana Nunes (right), KAUST professor of chemical and environmental science and engineering. Photo: KAUST / M. Weche

A recently published paper in Science Magazine, Polytriazole membranes with ultrathin tunable selective layer for crude oil fractionation, offers an innovative membrane development solution to handle unique industrial conditions, such as hydrocarbon fractionation.

Authored by a group of scientists under the direction of Dr. Suzana Nunes, KAUST professor of chemical and environmental science and engineering, and vice provost for faculty and adademic affairs, the paper highlights a versatile strategy to fabricate polytriazole membranes for energy-efficient crude oil fractionation. The membranes are also advantageous for their low carbon footprint properties and suitability to promote the circular carbon economy (CCE).

"I've been working on polytriazole membranes for more than twenty years," Nunes said. “In this paper, the approach was proposed by Dr. Stefan Chisca, research scientist in our lab. I'm always looking for polymers that can take challenges that are not possible with a very simple membrane."

Chisca specializes in developing polymers for membrane applications, with a focus on separation processes that involve minimal energy consumption. Before joining KAUST, Nunes led membrane research as the department head of Membranes for Sustainable Energy at Germany's Helmholtz Association.

While most commercially available membranes are built for water environments and room temperature, there's a unique challenge in developing stable membranes for harsher conditions characterized by elevated temperatures and a wide range of organic solvents and pH, such as the case for oil fractionation.

Meeting the separation challenge through thermal crosslinking

A crucial but highly energy-intensive and costly element common to chemical, pharmaceutical and petrochemical industries is the separation process required to purify solvents and chemicals, regulate solvent exchange, and manage catalysts. The most common separation techniques include distillation, adsorption, evaporation and extraction.

Membrane technology offers a low-carbon footprint alternative that is considered more sustainable. However, these industries find it difficult to replace conventional separation methods because they would need membranes to meet stringent mechanical and thermal stability requirements to prevent rapid physical aging and deterioration.

"The environment is rough at temperatures of more than 100 degrees, and what you fractionate could dissolve your membrane," Nunes said.

She pointed to the crucial crosslinking methodology using thermal treatment, needed to prepare the membrane to interact with the crude oil without completely dissolving. Polytriazole membranes have proven to be better suitable for separating complex non-aqueous mixtures. The KAUST team fabricated polytriazole membranes with 10 nanometer-thin selective layers containing sub-nanometer channels for the separation of hydrocarbons.

Using the combination of thermal crosslinking in tandem with the conventional non-solvent induced phase separation (NIPS), the treated polymeric membranes proved suitable for highly challenging chemical separation processes. The ultrathin selective layers and tunable properties of polytriazole membranes, such as permeances, allow them to adapt to a vast array of challenging liquid feeds, strong acids and complex mixtures like the ones found in crude oil.

Analytical characterization with the Core Labs

In order to better understand the membrane and solvent interactions, and also the chemical modification process through thermal treatment, Nunes' team worked with scientists at the KAUST Core Labs to fully characterize the membrane and oil itself. Different spectroscopic and microscopy methods were used to investigate the morphology of the membranes before and after crosslinking and follow the oil fractionation, resulting in the full characterization of properties.

"Our work with the Core Labs has been outstanding from day one," Nunes said. "This Science paper is an excellent example. Everyone involved is from KAUST, from our group to the Core Labs scientists. I think it's important to highlight that they are scientists trained in the frontier of these techniques. We could not do that alone."

Nunes credits the publication of the research to this collaborative effort.

Dr. Suzana Nunes (left), KAUST professor of chemical and environmental science and engineering, and Dr. Stefan Chisca (right), KAUST research scientist, examine a container of the polymer used to manufacture membranes in the Nanostructured Polymeric Membrane Laboratory, KAUST. Photo: KAUST / M. Weche

Applications for the Kingdom

Nunes believes that membrane technology could help Saudi Arabia save a lot of energy.

"The goal and the dream are to have large regional petrochemical companies use membrane technology as a substitute for part of their thermally driven separation processes," Nunes shared. "It's the reason why we're doing it. It's the motivation."

A big part of her group's work involves promoting the vision to develop membranes that are stable enough to be used in the chemical and petrochemical industries. The aim is to provide a viable alternative to classical separation methods, which require a multitude of steps and resources. Nunes also hopes to engage in more direct interactions with chemical industry players in the Kingdom to better understand their needs, and get more feedback on high-performing separation technologies done in organic solvents and elevated temperatures.

"This is the first step in a long story," she said. "There's more work to be done to scale up membrane production and have the technology be widely accepted for at-scale, non-aqueous industrial use."

On the horizon, Nunes also sees membrane technology as a viable solution to assist current efforts in minimizing carbon dioxide emissions by addressing the problem at the start of the industrial value chain. "I think it's much more effective to substitute part of the process employed in the chemical industry, which accounts for a very high carbon footprint," she said. If new plants being built in Saudi Arabia can incorporate novel and more sustainable membrane-based separation processes at the onset, it will greatly contribute to the circular carbon economy.”