Tiny algae have huge potential for Saudi Arabia’s bioeconomy

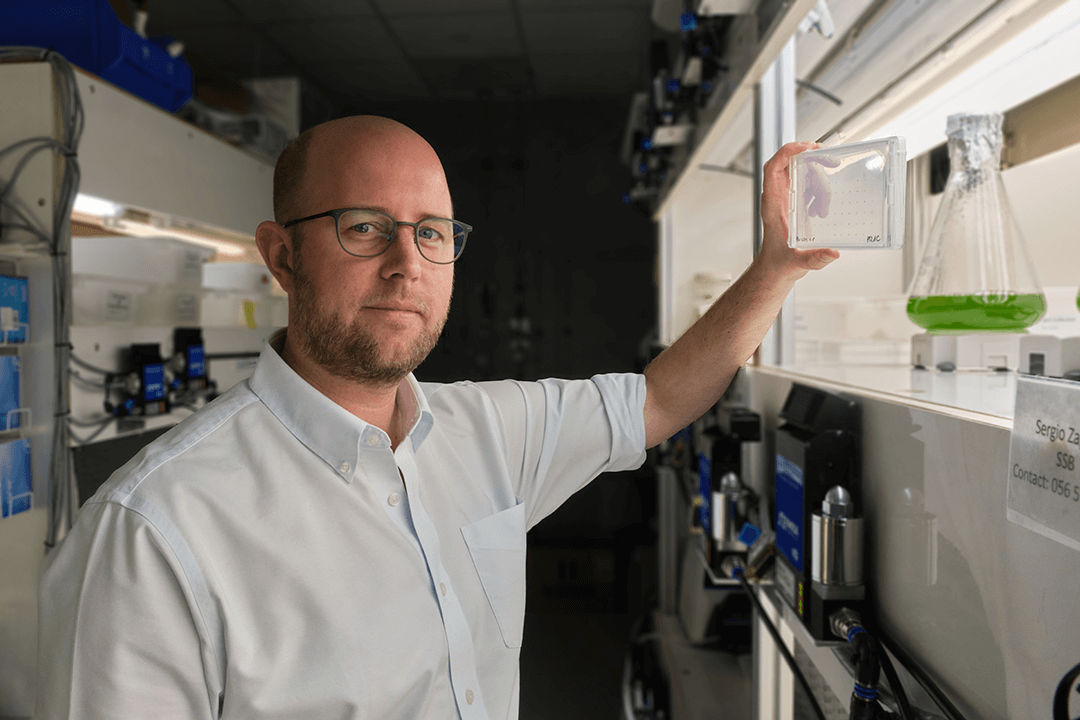

Dr. Kyle J. Lauersen at the KAUST Laboratory, which specializes in algae biotechnology.

An opportunity to build his own lab and the potential for his work to create a real impact in Saudi Arabia were two big motivators for Kyle Lauersen when he decided to accept a position at KAUST.

Almost four years later, Lauersen, an expert in algal synthetic biology and metabolic engineering, leads one of the only dedicated algal biotechnology labs in the Arabian Peninsula. His team isolates, identifies and characterizes algal species adapted to Saudi Arabia’s extreme temperatures and cultivates these local strains in 22 purpose-built bioreactors.

“We have probably the largest suite of bioreactors for growing algae of any academic institution in the world,” says Lauersen. “Every new strain is put in six reactors to grow under different conditions — continuous light, day-night cycling and then one reactor each to simulate winter, spring, summer and autumn in Saudi.”

“In one week we can test each of those conditions to see if the alga is going to perform well in spring or winter, or if it will grow well at a specific time and place: say, in August on the coast of the Red Sea.”

Algae are recognized for their ability to grow in waste waters, converting nitrogen and phosphorus, with carbon dioxide into biomass full of oil, protein, carbohydrates, pigments and clean water.

However, different species are needed for different conditions: the dairy industry, for example, produces waste water with very low pH. “We work with algae that grow at this low pH, so we can use them to clean up this waste water and, at the same time, they convert carbon dioxide into their biomass,” says Lauersen.

As well as determining the optimal conditions for growth for each new algal species, the researchers also characterize the algae and measure what they are producing, such as the amount of oil, protein and

carbohydrate. This is important information for people who want to produce algae, for example, for animal feed, but it is not a rapid process – identifying, isolating and characterizing each species can take several months.

“So far, we have isolated more than 60 strains and that number grows every week,” says Lauersen. We are building a living library, or biobank, that will serve as a natural resource for Saudi Arabia.

Lauersen works closely with the new pilot algal facility on campus supported by Ministry of Environment, Water and Agriculture. The facility is developing production of high-protein algae for aquaculture feed. Strains that show tolerance to the extremes of Saudi summer heat are passed to the pilot facility to grow and test productivity in outdoor conditions.

“It is important to interact with the players in the Kingdom who are growing the technology,” says Lauersen.

He also plans to develop a study program that will meet international standards in algal technology and education. “Our role is also to create educational programs to teach the next generation of bioprocess engineers to work with algae,” he says.